Basically the induction motor consists of two main parts, namely

- The part i.e. three phase windings,which is stationary called stator.

- The part which rotates and is connected to the mechanical load through shaft called rotor.

Stator

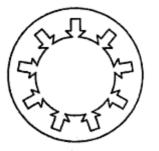

The stator has a laminated type of construction made up of stampings

which are 0.4 to 0.5 mm thick. The stampings are slotted in its

periphery to carry the stator winding. The stampings are insulated from

each other. Such a construction essentially keeps the iron losses to a

minimum value. The number of stampings are stamped together to build the

stator core. The built up core is then fitted in a casted or fabricated

steel frame. The choice of material for the stampings is generally

silicon steel, which minimises the hysteresis loss. The slots in the

periphery of the stator core carries a three phase winding, connected

either in star or delta. This three phase winding is called stator

winding. It is wound for definite number of poles. This winding when

excited by a three phase supply produces a magnetic rotating field as

discussed earlier. The choice of number of poles depends on the speed of

the rotating magnetic field required. The radial ducts are provided for

the cooling purpose. In some cases, all the six terminals of three

phase stator winding are brought out which gives flexibility to the user

to connect them either in star or delta. The Fig. 1 shows a stator

lamination.

|

| Fig. 1 Stator lamination |

Rotor

The rotor is placed inside the stator. The rotor core is also laminated

in construction and uses cast iron. It is cylindrical, with slots on

its periphery. The rotor conductors or winding is placed in the rotor

slots. The two typed of rotor constructions which are used for induction

motors are,

- Squirrel cage rotor and

- Slip ring wound rotor

Comments

Post a Comment

Comment Policy

We’re eager to see your comment. However, Please Keep in mind that all comments are moderated manually by our human reviewers according to our comment policy, and all the links are nofollow. Using Keywords in the name field area is forbidden. Let’s enjoy a personal and evocative conversation.