In order to reduce the effect of armature reaction following methods are used.

1) The armature reaction causes the distortion in main field flux. This can be reduced if the reluctance of the path of the cross-magnetizing field is increased. The armature teeth and air gap at pole tips offer reluctance to armature flux. Thus by increasing length of air gap, the armature reaction effect is reduced.

2) If reluctance at pole tips is increased it will reduce distorting effect of armature reaction. By using special construction in which leading and trialing pole tip portions of laminations are alternately omitted.

3) The effect of armature reaction can be neutralized by use of compensating winding. It is always placed in series with armature winding. The armature ampere conductors under pole shoe must be equal to compensating winding ampere conductors which will compensate armature m.m.f. perfectly.

4) The armature reaction causes shifting the magnetic neutral axis. Therefore there will be some flux density at brush axis which produces e.m.f. in the coil undergoing commutation. This will lead to delayed commutation. Thus the armature reaction at brush axis must be neutralized. This requires another equal and opposite m.m.f. to that of armature m.m.f. This can be applied by interpoles which are placed at geometric neutral axis at midway between the main poles.

Out of the different methods mentioned above, used to reduce the effects of armature reaction, let us see the method of providing compensating winding in detail. This method is very popularly used in actual practice for d.c. machines.

1.1 Use of compensating Winding

The compensating windings are basically used to neutralize the armature flux in the pole arc region which will otherwise cause sever distortion of main field flux. These windings are of concentric type and are placed in axial slots in the pole faces as sown in the Fig. 1.

|

| Fig. 1 Compensating winding |

The symbolic representation of compensating winding is shown in the Fig. 2.

|

| Fig. 2 |

The armature reaction causes the displacement of main field flux. It affects the waveform of main field flux and makes it non-uniform. The effect of armature reaction depends upon armature current which inturn depends on the load on the machine.

In case of machines having large fluctuations in load such as rolling mill motors or turbogenerators, the armature reaction will cause sudden shift of flux backward and forward direction depending on change in the load. This will cause statically induced e.m.f. in the armature coils whose magnitude depends upon how fast the load is changing and by what amount it is changing. There is dynamically induced e.m.f. in the armature coil also. Under worst conditions these two e.m.f.s may become additive. This will occur when load is increased on motor and decreased from generator. If this e.m.f. is more than the breakdown voltage across adjacent commutator segments, a sparkover may occur which can easily spread over as conditions near commutator are favourable for flashover. The maximum allowable voltage between the segment is 30 to 40 V. Thus there is always danger of short circuiting the whole armature if armature flux is not compensated.

This can be achieved by the use of compensating winding which will neutralize the effect of armture reaction. These windings are connected in series with the armature. The current in this windings flow in opposite direction to that in armature conductors below the pole shoes. This will counterbalance the cross magnetizing effect of armature reaction which may cause flashover between the segments.

Note : To have perfect neutralization of armature m.m.f. under the pole shoe, the ampere conductors of compensating winding must be equal to total armature ampere conductors under the pole shoe.

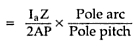

Ampere turns per pole for compensating winding

Since two conductors form one turn.

Since the distortion of armature m.m.f. and compensating winding m.m.f. is not identical the complete neutralization of armature m.m.f. can not be achieved by using compensating winding. The armature m.m.f. under the pole shoe is neutralized whereas there is incomplete neutralization in the interpolar region. There will be small flux density remaining unneutralized in GNA. This can be neutralized by using interpole windings.

Thus by using interpole as well as compensating windings, the armature reaction effect is completely neutralized over the entire armature periphery. The only flux present in the machine will be main field flux which will be an ideal situation.

Though compensating windings are very expensive they are provided in machines which carry heavy overloads or there is rapid change in the load. So that there will not by any possibility of flashover.

Example

Calculate the number of conductors on each pole piece in a compensating winding for a 10 pole d.c. generator which has lap wound armature containing 800 conductors. Assume ratio of pole arc to pole pitch to be 0.7.

Solution : P = 10 , Z = 800

Ampere turns per pole for compensating winding

Number of turns per pole for compensating winding

Since 2 conductors form one turn.

Compensating conductors / pole = 2 x 2.8 = 5.6 = 6

Comments

Post a Comment

Comment Policy

We’re eager to see your comment. However, Please Keep in mind that all comments are moderated manually by our human reviewers according to our comment policy, and all the links are nofollow. Using Keywords in the name field area is forbidden. Let’s enjoy a personal and evocative conversation.